Of the approximately 140 commercially available backsheet models, the 2023 Scorecard dataset includes 23 different backsheet models. None of those tested exhibited backsheet cracks following BDS testing. The outer layer of the tested backsheets used a variety of materials including fluororesin, PET, PVDF and PVF, and were transparent, white and black.

Key

Takeaways

BDS test results remain encouraging.

Cases of significant backsheet yellowing have been observed.

Recent BDS testing has revealed a few BOMs that exhibited notable discoloration (see the BDS Test Population Yellowness graph below). This can be indicative of material degradation, but not always. In these cases, Kiwa PVEL recommends that the manufacturer provide additional evidence to prove the backsheet will perform reliably for the expected module lifetime.

Other module materials susceptible to degradation.

In addition to some BOMs suffering backsheet discoloration, Kiwa PVEL found cases of other rear-side module materials degrading. These included module cables that had signs of chalking (a white powder on the cable surface), wet leakage test failures due to poor electrical insulation at the junction box, and power labels that became illegible.

Different backsheet repair solutions exist; testing is strongly recommended.

Kiwa PVEL has been contacted multiple times over the past few years by site owners with cracked backsheets where the module manufacturer recommended backsheet repairs. While repairing damaged modules may ultimately improve long-term reliability, Kiwa PVEL recommends qualification testing of repaired modules to prove longevity.

Test Result Spotlight

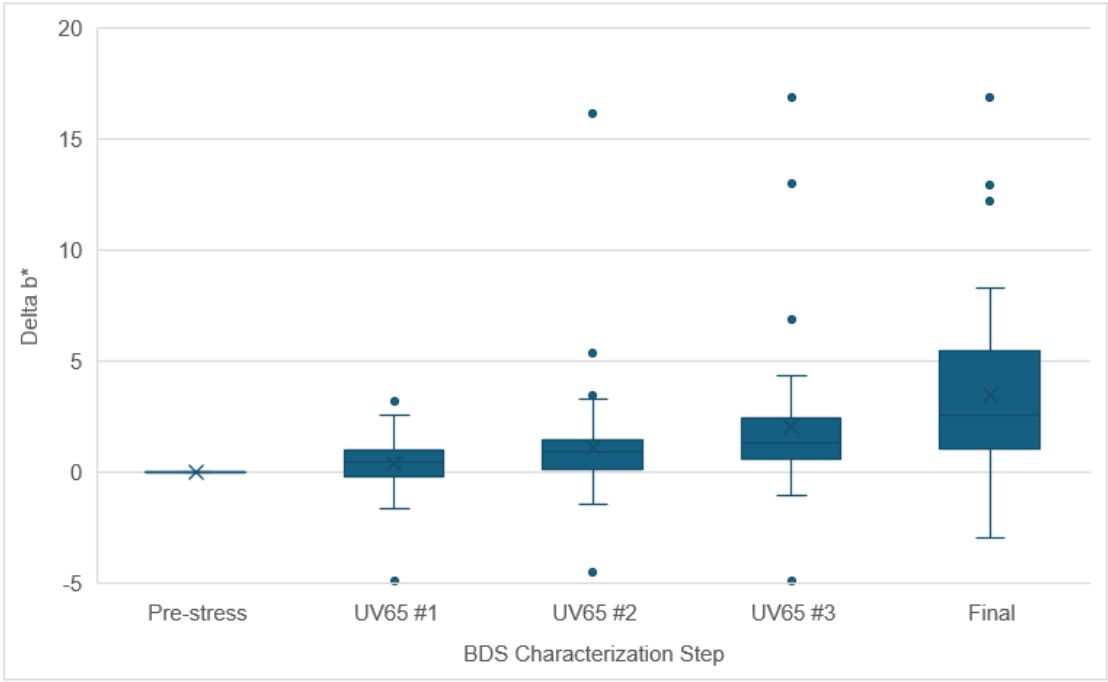

A recently tested BOM provided the most striking example of material degradation since the launch of the BDS testing in 2019. After the second round of UV exposure (i.e., following DH1000+UV65+TC50+HF10+UV65) the delta b* spiked to an average of 16.2. The modules also showed signs of a substance diffusing out of the backsheet and reacting with the moisture from the humidity freeze (HF) testing portion of BDS. This also resulted in the nameplate cracking and discoloring.

BDS Test Population Yellowness

During BDS testing Kiwa PVEL performs colorimeter measurements at 10 different backsheet locations for two identical samples per BOM. The measurements use the Commission Internationale de l’Eclairage (CIE) L*a*b* coordinate system, with b* representing the yellow/blue coordinate. As yellowness increases so does the b* value. BDS reports include a graph showing the average difference in b* values (“delta b star”) throughout BDS testing to help quantify the change in yellowness. A broad range of delta b* values have been measured across almost 70 BOMs of BDS testing, indicating that some BOMs are more vulnerable to yellowing than others.

A case study on why BDS is important, what PV module materials are assessed, and the test procedure for BDS can be found here on kiwa.com/pvel.

Procure better modules. Get access to the Scorecard data every quarter.

Sign up as a Kiwa PVEL Premium Partner