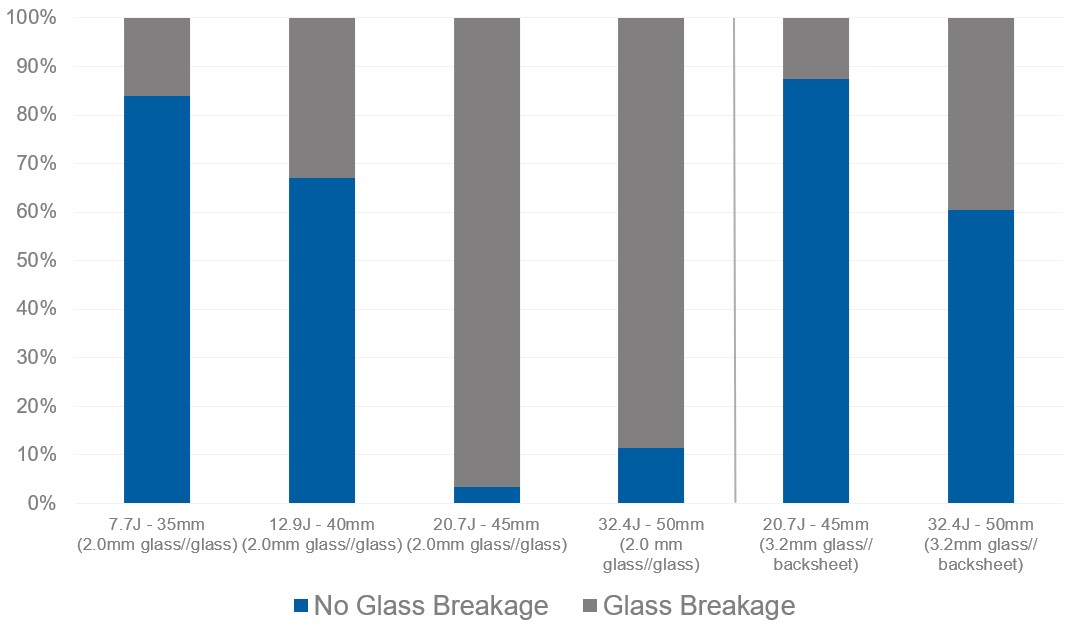

Kiwa PVEL hail test results show that 3.2 mm fully tempered glass//backsheet modules are significantly less susceptible to glass breakage than 2.0 mm heat strengthened glass//glass modules (see the Test Result Spotlight below). Our new HSS Top Performer category highlights modules resistant to glass breakage.

Key

Takeaways

Glass//backsheet modules have clear advantages.

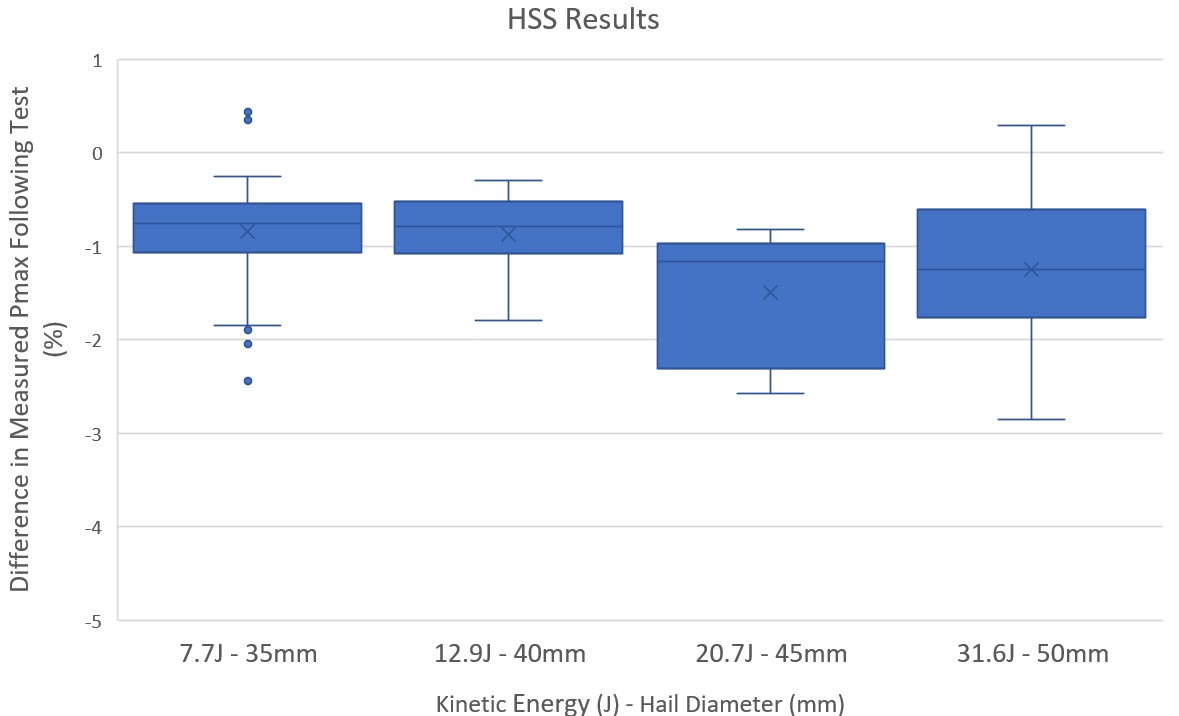

No hail-related power degradation > 3%.

Glass//glass modules have minimal power loss as cells are protected from cracking within the neutral plane. Glass//backsheet modules may experience cell cracks but ultimately suffer relatively little hail-induced power loss due to the use of half-cut, multi-bus bar (MBB) cells. See the Power Degradation graph below for more.

Many module manufacturers have hail resistant designs pending.

Kiwa PVEL’s hail testing has been almost exclusively for 2.0 mm glass//glass and 3.2 mm glass//backsheet modules, but three BOMs of 2.5 mm glass//glass have been recently tested and showed no glass breakage with 50 mm hail. More modules with thicker glass will be tested in the coming months as manufacturers look to increase hail resistance.

Failures stem from excessive retests and falling junction box lids.

Kiwa PVEL does not include glass breakage in the Scorecard failure data, but some manufacturers required multiple retests using the same hail diameter before achieving the desired hail test performance. Those cases are included in the failure statistics (and retests are noted in the reports). Three manufacturers also had modules where the junction box lid fell off due to hail impacts.

Test Result Spotlight

The glass breakage rates from Kiwa PVEL’s hail testing of almost 300 PQP modules is shown below, separated by 2.0 mm glass//glass and 3.2 mm glass//backsheet modules. The reduced hail durability of glass//glass modules is quite stark, with a breakage rate of 89% with 50 mm hail compared to 40% for glass//backsheet modules. Only the rear-side glass broke on 40% of the glass//glass modules that experienced glass breakage. The rear glass layer is typically weaker than the front due to the need for junction box holes and, in some cases, the colored ceramic fritting applied to the glass areas between cells to increase front-side power output.

Power Degradation of HSS BOMs

A case study on why HSS is important, what PV module materials are assessed, and the test procedure can be found here on kiwa.com/pvel.

Procure better modules. Get access to the Scorecard data every quarter.

Sign up as a Kiwa PVEL Premium Partner