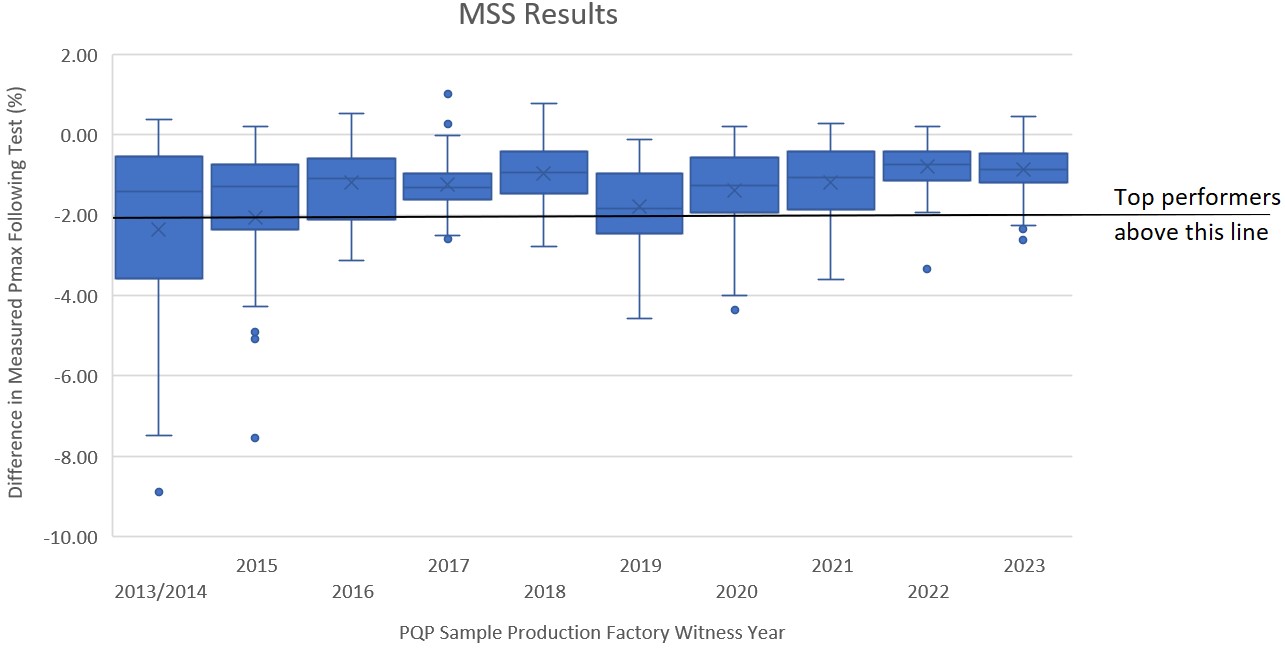

The power loss following MSS was quite similar for BOMs produced in 2023 and in 2022 (see the Power Degradation graph below for more). However, power loss from this test is expected to increase in the coming year with the test changing from traditional fixed-tilt mounting to more aggressive tracker or corner mounting.

Key

Takeaways

95% of BOMs completing MSS had < 2% power loss.

No cell cracks seen in glass//glass modules, but glass breakage is a risk.

While glass//glass modules have repeatedly been shown to protect the cells, Kiwa PVEL has received multiple reports of broken glass//glass modules in the field from locations around the globe. Most of this breakage did not occur during extreme weather events, leading to broken glass becoming a primary reliability concern.

High power loss for some glass//backsheet BOMs.

For glass//backsheet BOMs tested with both fixed tilt mounting (at ±2400 Pa) and 400 mm tracker mounting (at ±1800 Pa), the latter yield significantly worse results. Extreme deflection can push the backsheet and cells against the torque tube, leading to excessive cell cracking and, for one BOM, over 30% power loss.

7% of BOMs experienced one or more failures during MSS testing.

This is aligned with what was reported in the 2023 Scorecard. Nine manufacturers experienced at least one failure during MSS testing, all of which were due to visual inspection ‘major defects’, including glass breakage, frame breakage (see the Test Result Spotlight below) or delamination. See the Failures page for more.

Test Result Spotlight

While glass and cell cracking are key module durability concerns, frame fatigue can also be an issue. In this example, the module’s mounting hole was ripped out of the frame during tracker-mounted ± 1800 Pa SML and DML. This failure mode could result in modules becoming dismounted from racking during high wind events, and is likely due to using a thinner frame flange to save cost. This type of defect is typically not replicated during standalone SML or DML testing, but has been seen on multiple BOMs subjected to the PQP’s combination of SML and DML.

Power Degradation of MSS BOMs

Before 2019, all results are only DML+TC50+HF10. 30% of 2019 results and all post-2019 results are SML+DML+TC50+HF10.

Outliers with >10% degradation are not shown. In some cases, these cause a significant reduction in the mean.

A case study on why MSS is important, what PV module materials are assessed, and the test procedure can be found here on kiwa.com/pvel.

Procure better modules. Get access to the Scorecard data every quarter.

Sign up as a Kiwa PVEL Premium Partner