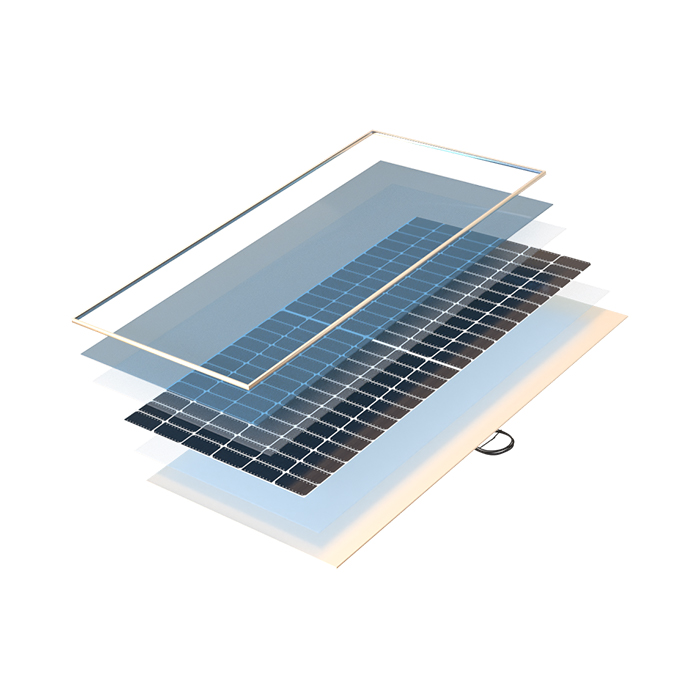

Frame & Adhesives

View DetailsGlass & Glass Coating

View DetailsSolar Cell Layer

View DetailsBacksheet or Rear Glass

View Details

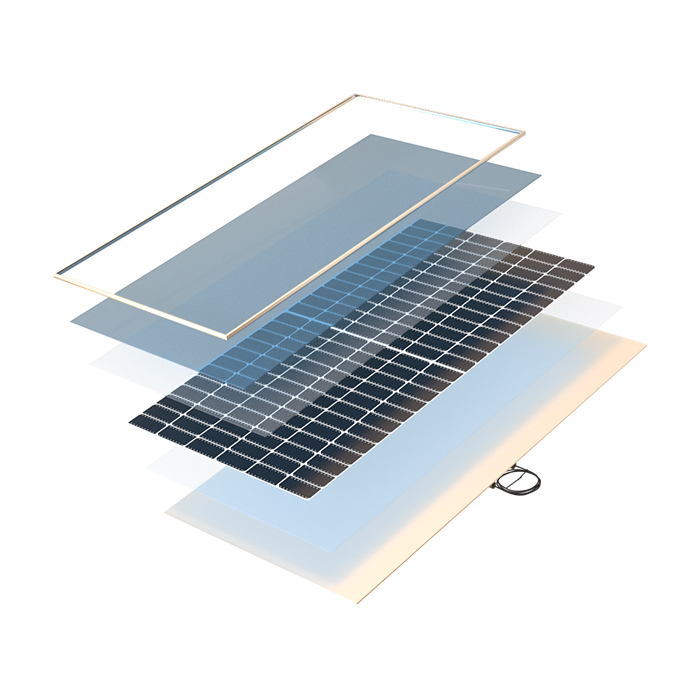

Frame

Provides mechanical reinforcement and allows the module to be mounted to racking. Improper frame design can lead to mechanical failure and/or cell damage.

Unique frame heights tested for this Scorecard: 5

Frame Adhesive

Adheres the frame to the module. Improper frame attachment can increase the likelihood of module damage and/or cell cracks.

Unique frame adhesive models tested for this Scorecard: 21

Front Glass:

Allows light to reach the cell while protecting the module from moisture and impacts. Glass cracks can lead to corrosion and safety issues.

Unique glass manufacturers tested for this Scorecard: 23

Glass Coating:

Anti-reflective coatings on the glass surface that increase module efficiency by reducing light reflections. Energy yield decreases when coating deteriorates.

Unique glass coating models tested for this Scorecard: 26

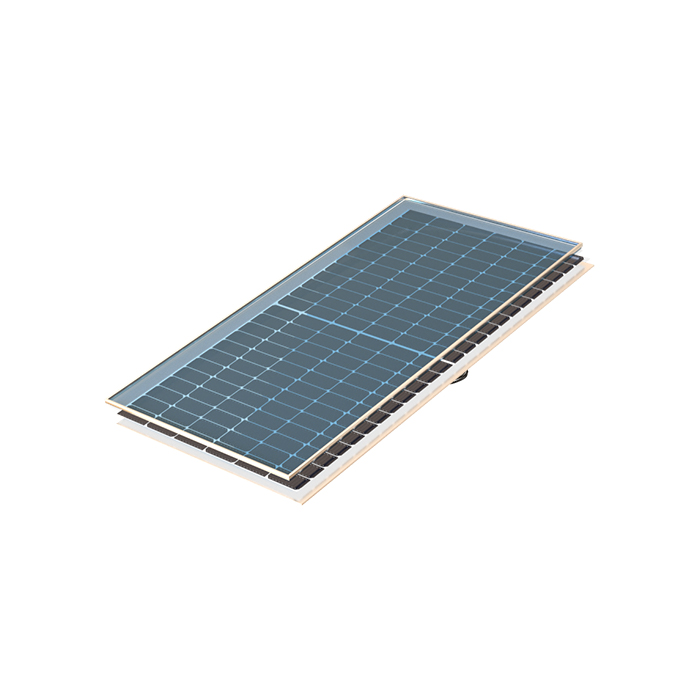

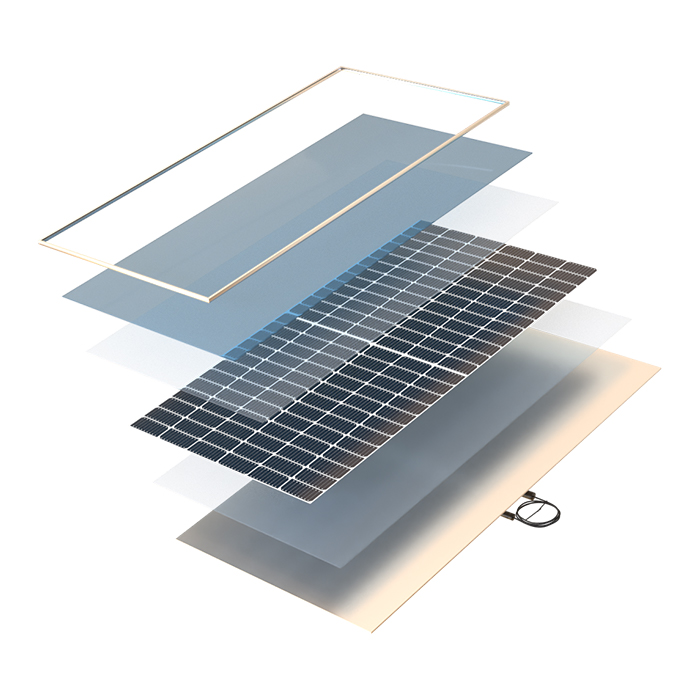

Front Encapsulant

Bonds solar cells to the front surface of the module. Degradation can result in discoloration, delamination and/or corrosion.

Unique front encapsulant models tested for this Scorecard: 33

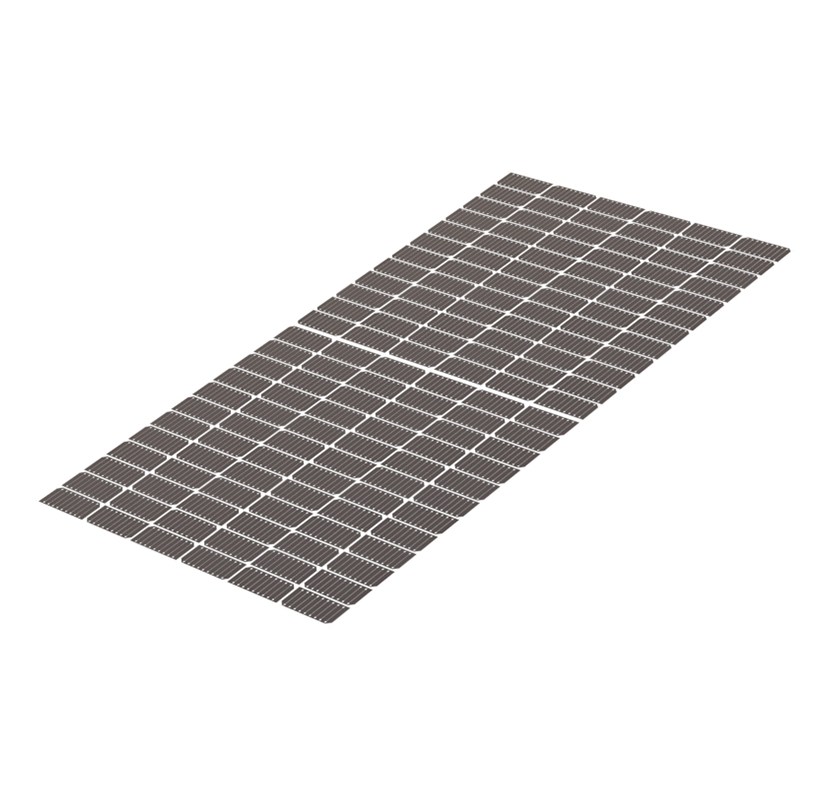

Cells

The cells capture sunlight and convert it to electricity. Cell issues can significantly reduce module power output.

Unique cell manufacturers tested for this Scorecard: 43

Interconnects

Cell interconnects provide contact between the cells and module conductors. Damage can cause loss of electrical current flow and/or hot spots.

Unique interconnect types tested for this Scorecard: 18

Flux

Cleans cell soldering areas, allowing for proper soldering to occur. Chemical reactions between the flux and other module chemistries can cause solder bond corrosion, leading to power loss and/or hot spots.

Unique flux models tested for this Scorecard: 37

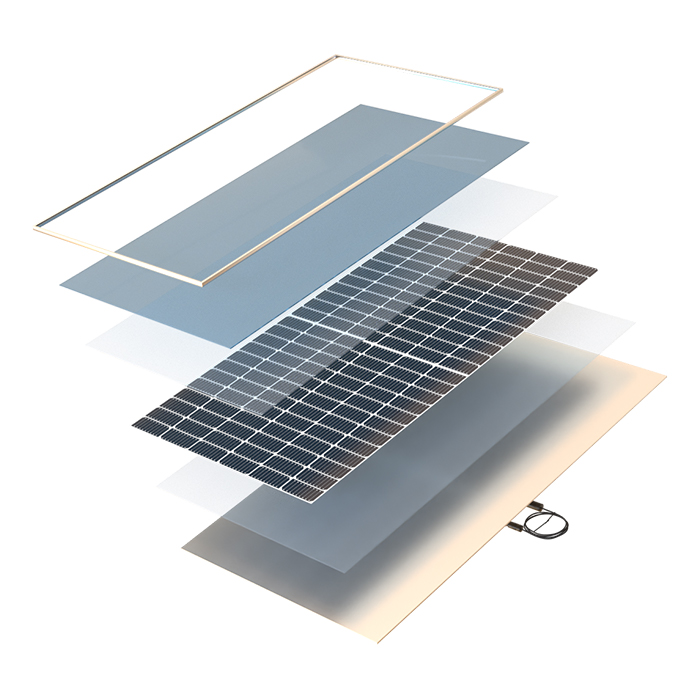

Rear Encapsulant

Bonds solar cells to the rear surface of the module. Degradation can result in discoloration, delamination and/or corrosion.

Unique rear encapsulant models tested for this Scorecard: 45

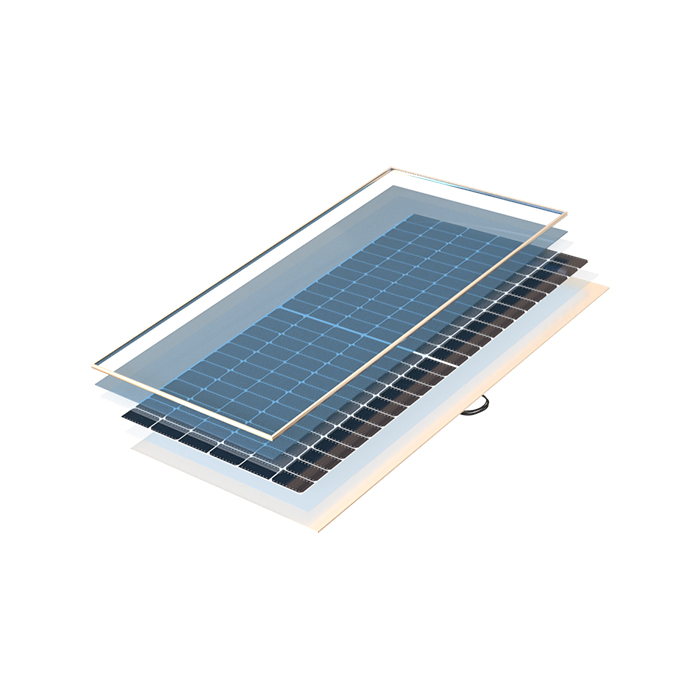

Backsheet or Glass

Covers and protects the back of modules. In bifacial modules, a transparent rear surface allows reflected light into the module. Cracked backsheet or rear-side glass can lead to delamination, corrosion and/or safety concerns.

Unique backsheet models tested for this Scorecard: 23

39% of BOMs used a backsheet; 61% of BOMs used rear glass.

Junction Box

Houses and protects the bypass diodes and electrical terminations between the inner module circuit and external cables. Junction box failure can lead to corrosion and/or electrical arcing and fire.

Unique junction box models tested for this Scorecard: 64

Junction Box Pottant

Seals and protects the inner junction box components. Poor quality pottant or curing lets moisture into the junction box, causing corrosion and/or junction box failures.

Unique pottant models tested for this Scorecard: 16

Diodes

Conduct current during module shading to prevent hot spot damage. Failed diodes can short circuit one third of the module output or allow hot spots that can create glass cracks and melt module materials.

Unique diode models tested for this Scorecard: 47

Junction Box Adhesive

Adheres the junction box to the module. Improper junction box adhesive can allow moisture ingress and safety issues.

Unique adhesive models tested for this Scorecard: 21

Connectors

The electrical connection point between modules. Connector mismatch or improper installation can cause open string circuits, arcing and/or fires.

Unique connector models tested for this Scorecard: 48